It is suitable for fried rice crackers, cat ears, shell crisps, sakima, various puffed foods and various shaped blanks.

Continuous fryer equipment can realize continuous automatic production of foods with processes such as frying and seasoning of large-volume puffed food. The frying time and speed are frequency-converted, which can meet the external filtering of different puffed foods. It can automatically filter and reduce the residue in the frying oil, which has a great effect on improving the cleanliness of frying oil. Reduce the manual investment and ensure the uniform quality of the product, so that the taste and color of the fried product can reach the best state.

The heat source can be natural gas, electricity, liquefied gas, light oil, heavy oil, and new material particle dyes, etc. The continuous fryer equipment can be customized according to the customer's production output, process, and plant layout.

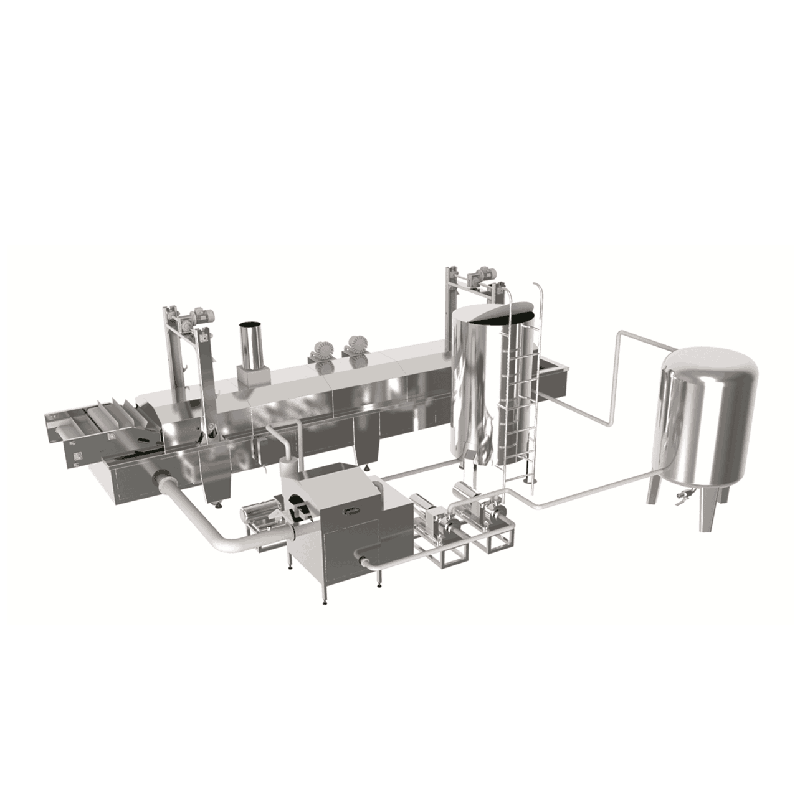

Fryer composition: tunnel fryer, coarse filter, fine filter, circulating oil pump, 2 oil storage tanks, external heater (fuel, gas type configuration), control part.

Continuous Fryer:

Mesh belt model: punching screen, aperture 1.5-3mm

Layers of mesh belt: single layer top pressure mesh belt (floating puffed food)

Double-layer push-down support net belt (sink first and then float puffed food)

Material: Stainless steel

Performance characteristics: The frying net belt can be raised and lowered, which is convenient for cleaning the bottom of the pot. Electric heating is built-in heating to reduce the oil capacity. The oil circulation direction inside the boiler body follows the feeding direction

Strainer:

Double-layer circulation filtration, filter residues are kept in the filter box to ensure the quality of frying. Filter box dimensions: 1000 * 1000 * 1100mm, automatic replenishment valve is installed inside the coarse filter, connected to the oil tank, 3 ports are reserved, oil inlet, oil outlet, sewage outlet, coarse filter housing with insulation Function, with insulation layer, improve safety performance and reduce heat energy consumption

Circulating oil pump:

Equipped with a turbo-type heat-conducting oil pump, with a large flow and easy maintenance. Different models of oil pumps are configured according to different lengths of fryer. Oil pump power: 1.5-4kw

There are 2 oil tanks with a capacity of 1-3m³. One is filled with new oil, and the other is the oil filtered by the fine filter. The oil tanks have the function of electric heating and heat preservation and outer insulation.

Fine filter:

When the fine filter is stopped, the fine oil is filtered by using the oil inside the deep fryer, and the filter fineness is above 200 mesh to ensure that the oil is as clean as new. 1.5m³ per hour. The power is 3kw.